WHITEPAPER

FEATURE ARTICLE

Discover the significant benefits that can be tapped into when adopting the use of plant-based additives for food packaging polymers.

Plastic materials based on mechanically or chemically recycled post-consumer products as well as non-fossil resources are gaining more and more acceptance among brand owners, designers and OEMs, especially in the packaging industry. However, ‘minor’ components such as additives are often still overlooked, although they can have a crucial effect on the processing, handling, functionality and sustainability of new materials.

Consumers love ‘bio’ and have been spending a steadily rising percentage of their personal budgets on food, skincare and other daily products with more natural ingredients, which are perceived as being healthier than common synthetic alternatives. At the same time, manufacturers and end-users are increasingly ‘going natural’ to mitigate their impact on fossil depletion, relieve their carbon footprint and help reduce plastic waste.

In addition, efficient packaging materials can make a significant contribution to the reduction of food losses in a hungry world by extending the shelf-life of products. This is where our Einar® plant-based food-grade polymer additives come into play. Backed by our extensive expertise in food emulsifiers, they lend instrumental properties to food packaging plastic solutions.

Essentially, most Einar® polymer additives are ‘dual use’ products, which means they can serve both as emulsifiers in food and as surfactants or modifiers in non-food items, namely in food-contact plastic packaging and containers. In other words, they are safe to eat and will not alter the taste of the food, while extending its shelf and storage life. Two of the most instrumental properties to these ends are the prevention of fogging and static build-up.

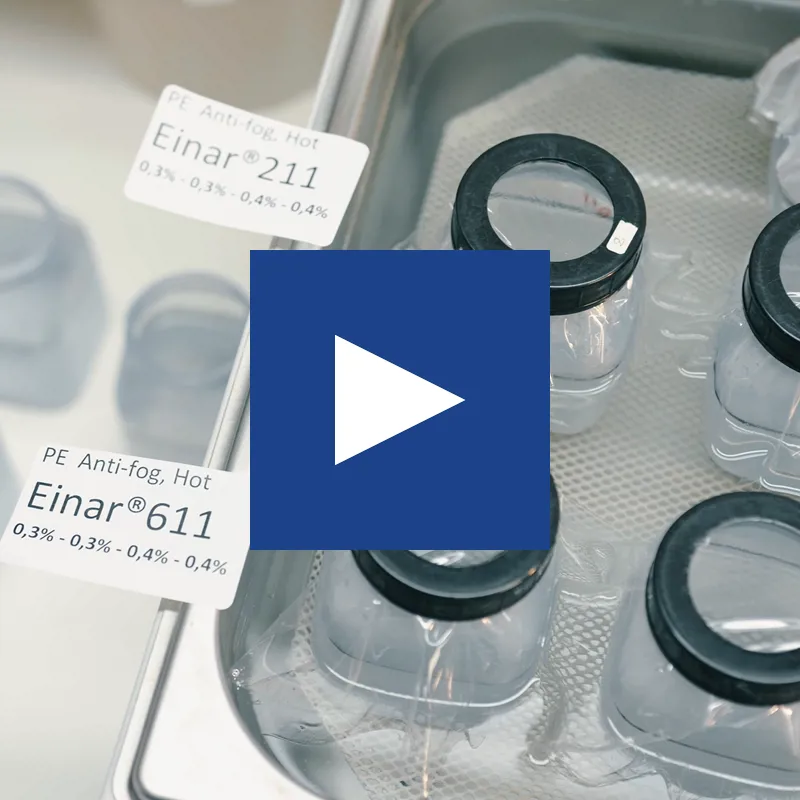

Transparent food packaging films and containers require long-lasting clarity to maintain the aesthetic consumer appeal of the packaged product. Varying conditions of ambient humidity and temperature in these applications can cause the formation of condensation droplets and fogging on the inner surface. Einar® plant-based anti-fog additives effectively lower the surface tension on the inside so that the moisture will spread as a continuous thin film across the surface. Apart from preserving the clear view of the food, this also protects its freshness and extends its shelf-life.

Another desirable property of food packaging products is anti-static behaviour. Static attracts dust and other fine particles, which again means lower transparency and creates an unhygienic look of the product. Just as important, static on plastic surfaces can result in a number of serious problems during processing, from reducing the feasible rolling speed in film production and causing congestions on conveyor belts to creating handling problems during stacking and complicating the sealing of packages for powdery products. Einar® anti-static additives interact with ambient moisture to create a conductive layer on the packaging surface that will dissipate the static.

All these functional benefits are provided at much lower concentrations than required when using conventional fossil-based amine or amide additives. As polyglycerol esters or glycerol mono-stearates, Einar® polymer additives are made exclusively with fatty acids sourced from vegetable oils, including certified segregated palm oil. All are FDA and EU-approved for food-contact applications, and produced in factories with a strategic focus on reducing our energy consumption and our CO2-emissions. This gives them a perfect fit in innovative new packaging materials and makes them an excellent replacement in existing packaging formulations, facilitating the switch from fossil to more responsible bio-based resources.

Typical applications include polyolefin (PP, PE) film, injection moulding and foam materials. In other areas, Einar® plant-based additives are used as ageing modifiers in PP and PE foams, coating powders for EPS, mould release agents, and pigment dispersants in colour masterbatches.

Customers who wish to evaluate the functional and performance benefits of Einar® vs. common synthetic additives are supported by our large-scale Polymer Innovation Centre in Denmark. The Centre is fully equipped for testing new plant-based additive, masterbatch and plastics solutions from detailed material analyses to processing trials.

WHITEPAPER

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE