WHITEPAPER

FEATURE ARTICLE

Consumers are increasingly interested in both food ingredients and the safety of the packaging that protects them. By applying the proven capabilities of plant-based emulsifiers to polymer materials, manufacturers can improve functionality and support compliance with recognised food-contact standards – while optimising production efficiency.

"Commonly used food emulsifiers such as polyglycerol esters (E475) and mono- and diglycerides (E471), known as glycerol monostearate (GMS) in the polymer industry, offer a responsible alternative to conventional additives. They combine reliable performance with opportunities for process optimisation and cost-efficiency – helping producers meet technical and regulatory requirements without compromising quality."

– Bjarne Nielsen, Business Development Manager

Invented in 1917 by Palsgaard founder, Einar Viggo Schou, the modern emulsifier was originally intended to reduce spattering in margarine. Since then, the use of emulsifiers has become much more widespread, with applications ranging from prevention of heat shock in ice cream to viscosity control in chocolate, and aeration in baked goods – and most recently, as a functional polymer additive.

Ask a polymer producer or masterbatcher which emulsifiers he is using, however, he’ll most likely not know what you are talking about.

“Essentially, emulsifiers allow oil and water to mix and form a stable emulsion, which is very useful in food production”, explains Bjarne Nielsen, Business Development Manager for Bio-Speciality Additives at Palsgaard. “When used in polymers, however, emulsifiers have different functionalities, making them suitable as anti-fogging and anti-static additives as well as dispersing aids”, he continues.

Traditionally, petrochemical-based additives have been used to deliver these functionalities but, as consumers become increasingly concerned about possible migration from the plastic packaging into food products, plastic manufacturers have started to explore safer and more sustainable solutions.

"Commonly used food emulsifiers such as polyglycerol esters (E475) and mono- and diglycerides (E471), known as glycerol monostearate (GMS) in the polymer industry, offer a responsible alternative to conventional additives. They combine reliable performance with opportunities for process optimisation and cost-efficiency – helping producers meet technical and regulatory requirements without compromising quality", says Bjarne Nielsen

Just as consumers tend to avoid products with an unclear, condensed surface, so too, are they put off by dust-covered packaging. Due to the static nature of plastic packaging, it easily attracts dust, particularly in low humidity, and can potentially damage the aesthetic appeal of the product. In addition to attracting dust, the build-up of static charges in plastics can cause problems for plastic packaging manufacturers:

“Efficient anti-static additives can dissipate charge from a polymer surface and prevent a static charge build-up, which means that dust and other fine particles will not be drawn to the packaging surface and the product will maintain a clean and attractive appearance”, explains Bjarne Nielsen.

Anti-static additives work by migrating to the polymer surface, where they interact with ambient moisture, creating a conductive layer that can dissipate the charge.

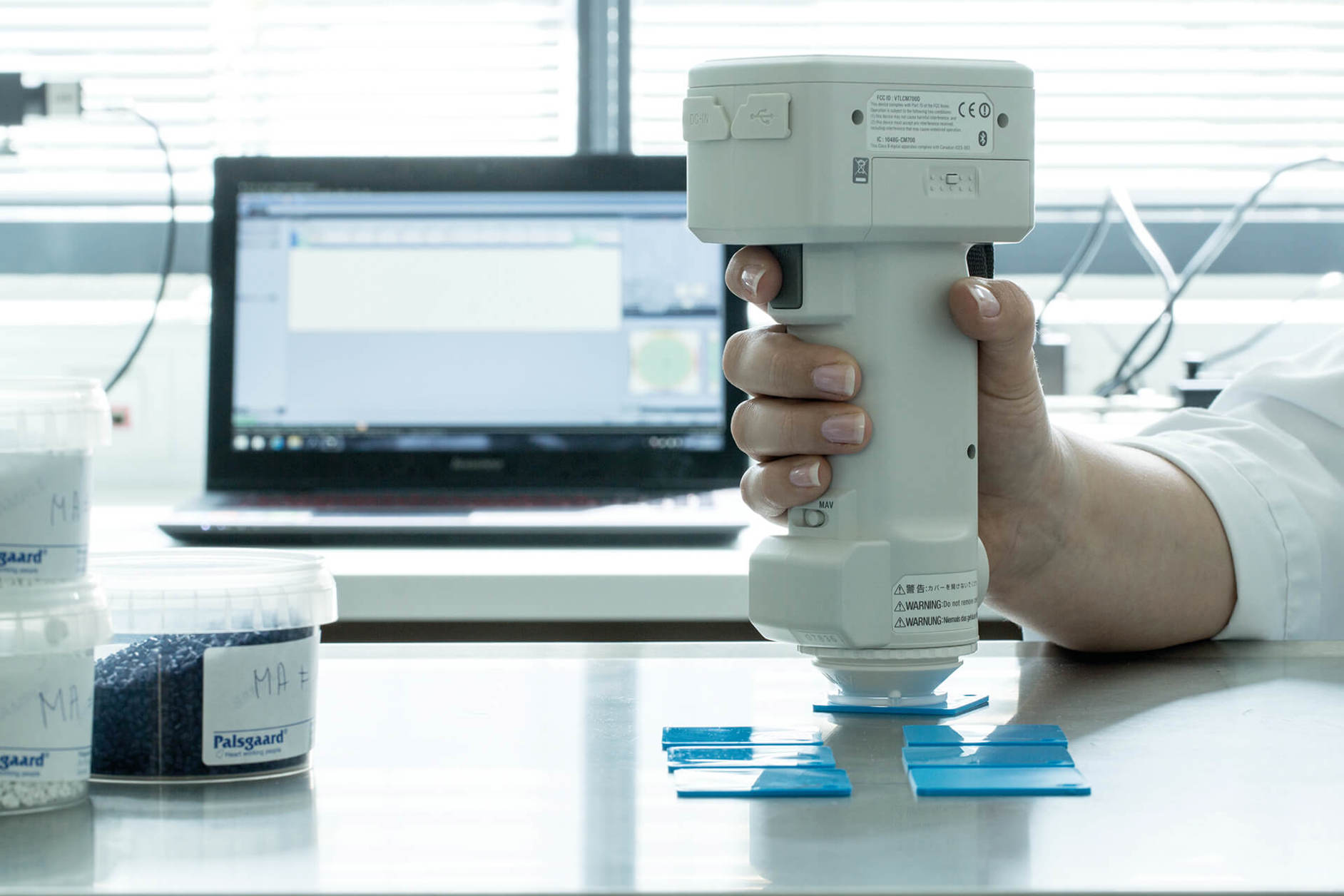

Supported by 100 years of experience in developing and perfecting emulsifiers used in food, Palsgaard’s R&D staff have unique insight into the molecular behaviour of the many different substances that make up emulsifiers. This has enabled the development of innovative, efficient, safe and renewable possibilities for the polymer industry – and Palsgaard’s series of dispersing aids is a good example:

Traditionally, powdered, petrochemical-based waxes have been used to coat the colour pigments and help distribute them in the polymer product. Mixing the waxes with the expensive colour pigments, however, is a dusty affair. This is likely to be a concern for workplace safety – and to result in sub-optimal distribution of the colour pigments.

By adding Palsgaard’s patented, liquid emulsifier-based dispersing aid, colour masterbatch manufacturers can achieve a safer production process and much better distribution of colour pigments. In fact, the emulsifier is so efficient that pigment loadings can be significantly reduced while still delivering the desired colour strength, allowing considerable cost-savings as well as a more sustainable polymer profile.

As an added benefit, colour masterbatch producers will also be able to improve production processes, since the equipment becomes much easier to clean when switching to other colours.

“Our production sites operate with a strong focus on reducing energy consumption and CO₂ emissions,” explains Bjarne Nielsen. “We also offer palm-based emulsifiers as RSPO SG or MB-certified—a practice that extends to our polymer additives, supporting responsible sourcing.”

For plastics manufacturers and polyolefin suppliers, partnering with Palsgaard means access to innovative solutions and technical expertise that help meet evolving market requirements for performance and sustainability.

With a commitment to food-contact safety and resource efficiency, Palsgaard continues to develop polymer additives that align with recognised standards and industry goals for circularity and responsible production.

“We have invested significantly in technology and laboratory facilities to support customer needs,” Nielsen adds. “Our aim is to create partnerships that deliver value through reliable performance, process optimisation, and compliance with sustainability objectives.”

WHITEPAPER

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE