FEATURE ARTICLE

FEATURE ARTICLE

As the focus on plastic increases, it is becoming ever more important for producers and processors to choose additives that can be used in sensitive applications such as food packaging without concern for food safety or the environment. As a food scientist, you might wonder what emulsifiers can do in plastic applications. The following ten questions might have popped up in your mind when hearing about emulsifiers as plastic additives:

Emulsifiers such as GMS (Glycerol Monostearate) have been used in the polymer industry for more than thirty years, primarily as anti-static additives, but as the understanding of emulsifiers increased in the food industry, more and more emulsifiers are used in plastics in a large variety of applications.

Many of the very same emulsifiers used in food have proven effective as polymer additives. As an example, we can take an emulsifier from a margarine recipe and incorporate it into plastic to achieve an anti-static effect. However, the diverse emulsifier chemistry can also be used to make completely new and tailor-made molecules which are optimized for each specific application in plastics.

One of the great strengths of using emulsifiers as polymer additives is the inherent food-grade status. They represent a group of safe and non-hazardous additives in a world where increasing attention on additives in plastic packaging has resulted in more regulation and control of what comes in direct contact with food. Thereby, emulsifiers present themselves as effective alternatives to current additives of concern. It is, however, possible to make non-food grade derivatives of emulsifiers which are then used outside of food packaging applications.

Most of the emulsifiers are mixed into the polymer, much like margarine in a dough, after which the polymers are shaped, not into cookies or muffins, but into long sheets or objects through extrusion or injection moulding. After production and depending on the emulsifier, it will migrate to the surface instantly or within days where it will position itself in the interface between plastic and air. Here it will make the plastic surface more water-loving, thus attracting minuscule amounts of water which helps dissipate static electricity, making the surface anti-static or it can spread the droplets on a foggy surface into a clear water film, giving an anti-fogging effect.

In some cases, with specifically engineered emulsifiers or blends, superior performance can be achieved, but in others, they simply meet the current standards in the industry. In addition to their performance, one of the greatest strengths of emulsifiers is the combination of food-grade and their bio-based nature which frees them from much of the concerns currently surrounding polymer additives used by the polymer industry today. And with increasing customer demands for safe packaging, this trend will only get stronger as legislation continues to tighten in years to come.

The key is the amphiphilic nature, that it is both hydrophilic and lipophilic, which is also utilised in food applications. However, instead of acting in the oil/water interface they migrate to the surface of the polymer to the polymer/air interface. This migration is very much controlled by the polymer type and its crystallinity, but the chemical buildup of the emulsifier also plays a big role. Shorter-chained glycerides migrate to the surface almost instantly during processing which makes them good for mould-release in injection moulding or when an instant anti-static effect is needed in further processing. Medium and longer chained glycerides can take days to reach the surface and thereby give a delayed effect, which in turn often lasts longer. Polyglycerols of the same types of fatty acids have also shown very good performance in challenging applications such as anti-fogging in green-house film where a long performance is needed.

One of the challenges for the polymer industries with these products is their physical appearance. Some are pellets which can be handled by many producers, but some are paste-like or liquid. This means that the producers must heat them and dose them as a liquid which can be hard to handle on an extrusion line if they don't have the right equipment. This is also why one of the biggest customer segments for emulsifiers used as polymer additives is masterbatch producers. They can blend the additives with the polymer on their extrusion lines creating a concentrated mix, a masterbatch, in pellets which is easy to handle for converters who shape the plastic into usable pieces such as chairs or buckets.

Another drawback is the need to hit the right concentration. This is most often not a problem, but unfortunately, it isn't so that the effect gets better the more you put in, just as too much emulsifier can create an undesirable crumb in a cake or make the chocolate too viscous. In the case of polymer additives, too much emulsifier will cause excessive migration to the surface creating a visible, greasy layer on the plastic surface – much like fat blooming in chocolates. In the case of, for example, a black and shiny coffee machine, you wouldn't want a milky layer like this on the surface and at that point, when the product starts to bloom, it no longer gives the anti-static or anti-fogging effect. Therefore, it is important not to overdose when using emulsifiers as polymer additives.

Emulsifiers show excellent performance within several applications in plastics.

Emulsifier performance in various applications is evaluated quite differently from the food industry as texture, emulsion stability and water content are not used in the evaluation of polymer additives.

After being processed into a film or an injection moulded piece, the anti-static performance of the final product is evaluated through static decay time or surface resistivity. Static decay time is an expression of how long it takes the surface to discharge from 5000 volts to 500 volts i.e. 10% of the charge. A pure polymer will not even be able to charge to the 5000 volts required to begin the experiment and a good anti-static additive will show a static decay time in less than 2 seconds. In surface resistivity, a current is run through two electrodes at a given distance on the surface of the plastic piece and the resistance of the surface is determined over the measured area. An anti-static surface is in the range of 1010-1011 ohm/square, while the pure polymer is insulative with a surface resistivity at 1012 ohm/square and up.

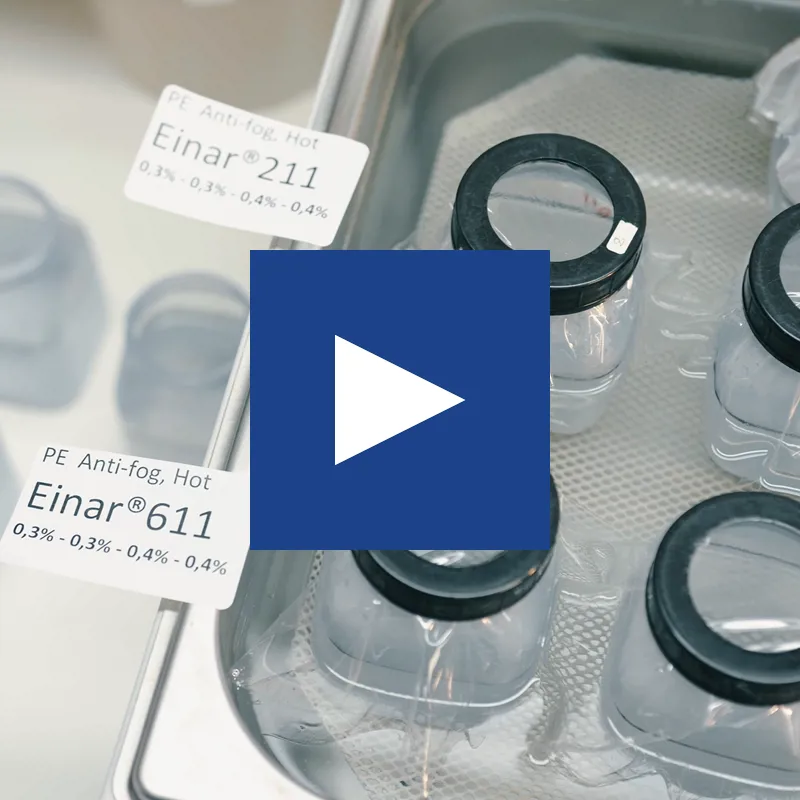

The anti-fogging performance of plastic films is evaluated visually on a scale from A to E, where A is completely fogged with very small droplets and E is a transparent film with no droplets. The film is fixed to a container with water and the evaluation is then performed at either 5 °C in a refrigerated environment, to simulate cold storage of for example salads and meat, or in a water bath at 60 °C to simulate hot applications such as newly cooked meals.

Plant-based emulsifiers are especially well-suited for both bio-based and biodegradable plastics. Here, it is important to distinguish between the two types of “bio” plastics.

Bio-based means originating from bio-based materials high in carbon, such as sugar cane. This type can be transformed into an exact copy of their fossil-based counterparts, such as PE (polyethylene), which are not biodegradable. Thereby, emulsifiers can be an effective and safe additive in bio-based plastics just like in their fossil-based counterparts.

PLA (polylactic acid) is an example of a polymer which is both bio-based and biodegradable. The biodegradability in PLA is inherent, due to its ester backbone, which, like the emulsifiers, will break down to non-harmful compounds under hydrolysis. This makes emulsifiers an obvious candidate for additives, as it is fully biodegradable and safe for the environment.

Therefore, emulsifiers are an excellent choice for both bio-based and biodegradable plastics, which is a growing segment in the plastics industry as consumers are demanding greener alternatives, free of fossil fuels. Recently, scientists are even working on polymers based on CO2 from the air, to help clean the atmosphere of excess CO2, which is the perfect raw material for carbon-based polymers.

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE

WHITEPAPER