FEATURE ARTICLE

FEATURE ARTICLE

Electronic packaging demands efficient anti-static solutions that work well under low humidity conditions without causing unwanted side effects.

This article delves into the importance of stability at low humidity and reduced oiliness in electronic packaging.

When looking for efficient anti-stats for electronic packaging applications, it’s a requirement that they function well at low humidity conditions and that they cause no negative effects such as stress-cracking of polycarbonate and that they cause no oily residue on the packaging surface.

Conventional anti-stats such as ethoxylated amines and diethanolamide are known to cause stress-cracking and in the case of amides lead to excessive migration resulting in the development of an oily residue on the packaging film.

By switching to Einar® 601, a plant-based anti-static additive, manufacturers of polyethylene electronics packaging can overcome these challenges and benefit in several ways:

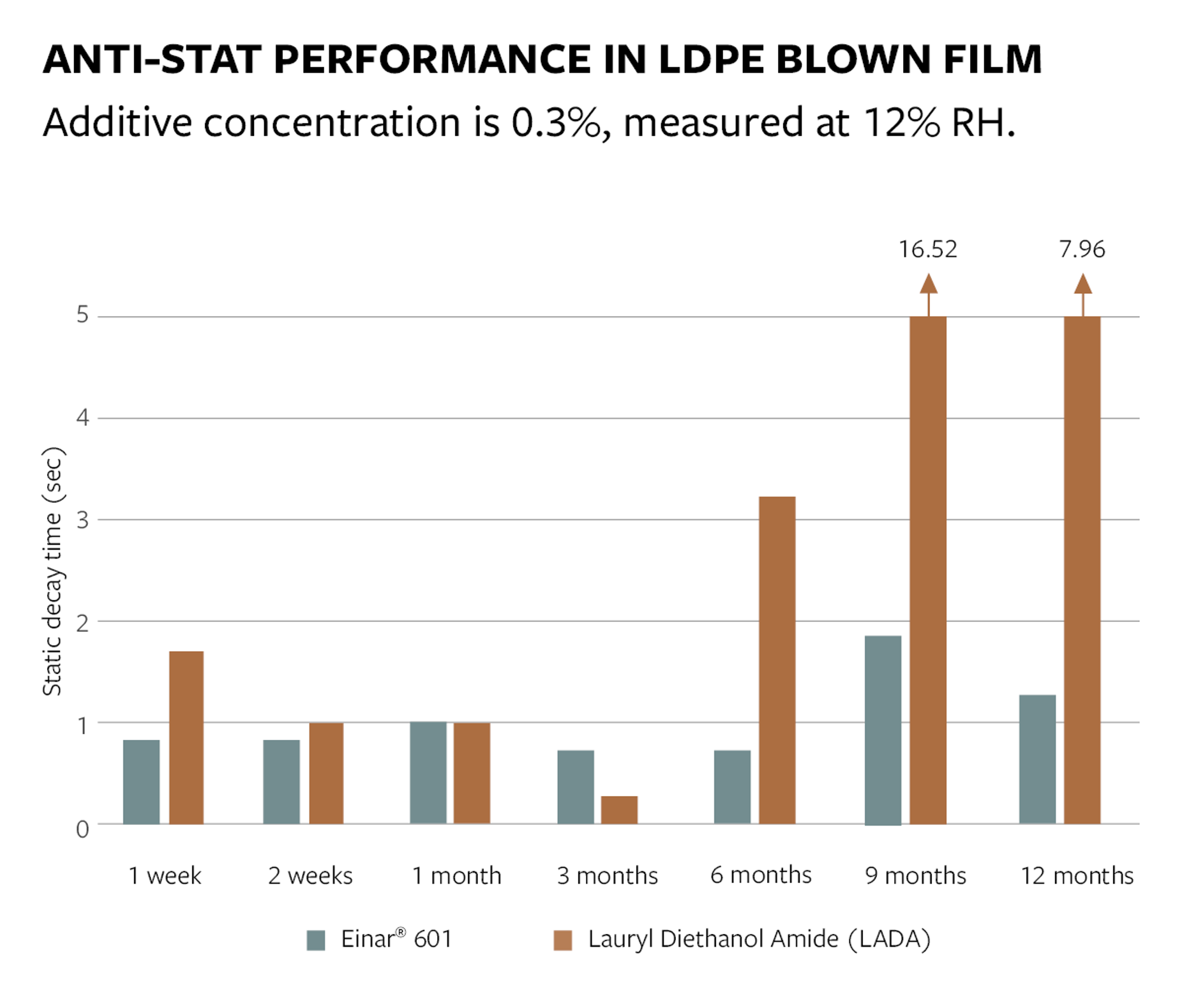

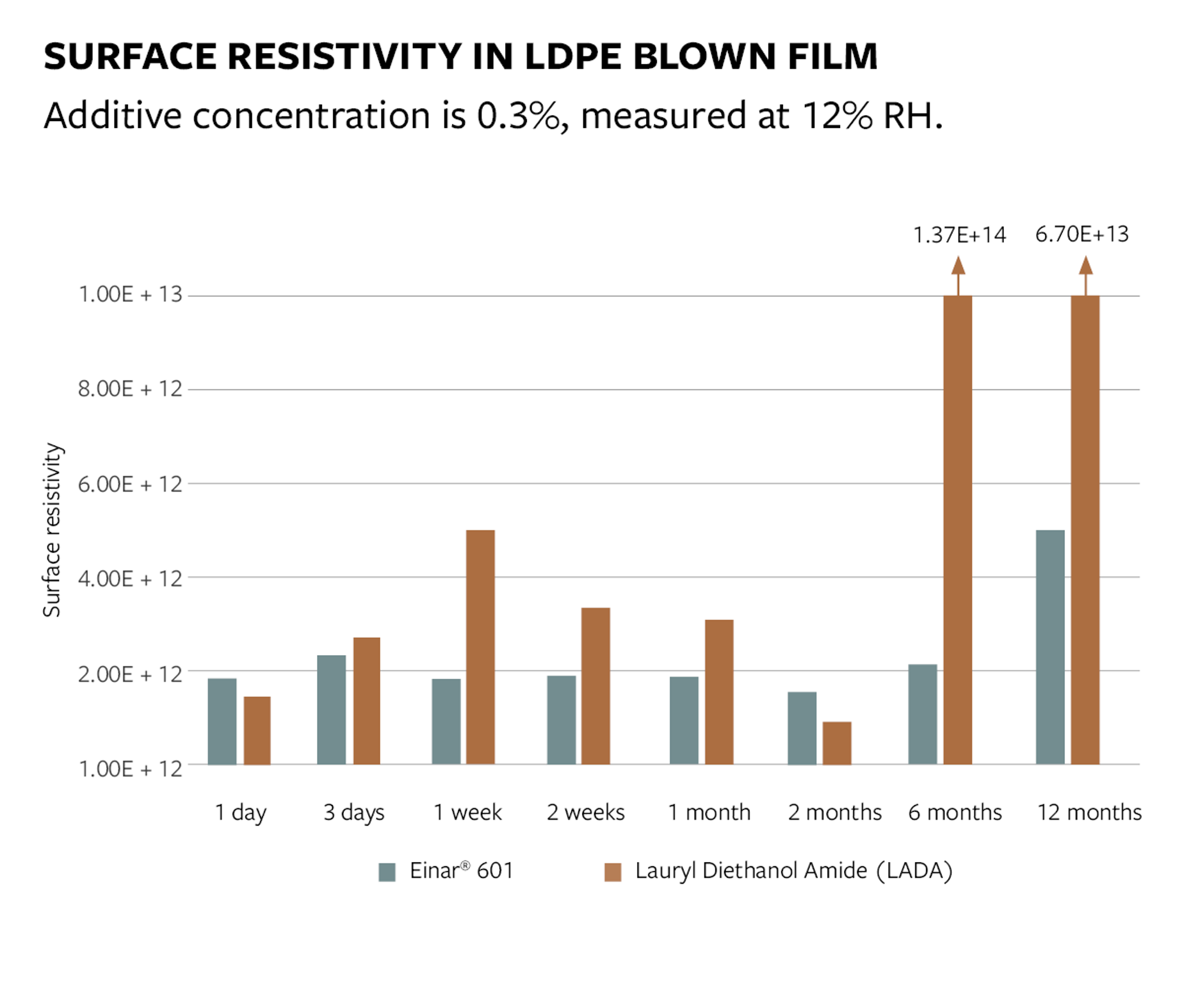

Einar® 601 is specifically formulated to maintain its effectiveness in low humidity conditions. It provides consistent static control, reducing the risks of electrostatic discharge damage to sensitive electronic components.

PC is a popular material for electronic components due to its mechanical strength and dimensional stability. However, using traditional additives can lead to stress-cracking in PC, compromising safety and functionality of the finished product. Einar® 601 offers excellent compatibility with PC, ensuring that stress-cracking risks are minimised.

Traditional anti-static additives may leave an oily residue on the packaging film, making it difficult to handle and potentially contaminating the electronic components. Einar® 601, in contrast, produces less oiliness even at the same typical dosage, improving manufacturing efficiency and product quality by keeping the film clean and easy to handle.

By making the switch to Einar® 601, manufacturers can achieve improved performance, prevent stress-cracking, minimise oiliness and reduce costs in their electronics packaging, particularly in low-humidity conditions.

Palsgaard offers technical support and expertise to assist manufacturers in the proper utilisation of Einar® additives. This guidance ensures that manufacturers can effectively incorporate the additives into their production processes while maximising safety and performance.

FEATURE ARTICLE

FEATURE ARTICLE

TECHNICAL ARTICLE

FEATURE ARTICLE