FEATURE ARTICLE

TECHNICAL ARTICLE

Food-grade plant-based anti-static additives deliver optimum migration performance in polypropylenes for long-lasting dust-free surfaces and clarity of thin-wall packaging.

As brand owners and manufacturers are seeking to minimise their carbon footprint and reduce the consumption of raw materials, there is an increasing demand for plastics that will enable durable thin-wall packaging designs without compromising the protection of the packaged products. However, a ‘minor’ detail that is often still overlooked in the quest for more sustainable packaging is the additives used in the material to maximise processability, handling and shelf-life.

Plant‑based additives offer strong performance with added benefits for handling and recyclability considerations, while delivering effective static control.

Static build-up is the single most frequent source for the accumulation of dust and other fine particles which can severely impair the attractive look of packaged products, ultimately even leading to food waste due to poor consumer acceptance. While static energy is often not an issue during summer when humidity is normally higher and makes the air more conductive, it can be a huge problem during winter or more generally in colder climates.

The market of injection moulded food and non-food packaging is dominated by random polypropylene (PP) copolymers, and PP block or impact PP copolymers. As highly versatile materials, these PP polymers are used in a wide range of different markets, including medical, food and consumer goods packaging – all of which require anti-static properties in some form. Notably, impact PP copolymers are by far the most important materials especially for food containers since they offer outstanding low-temperature impact resistance.

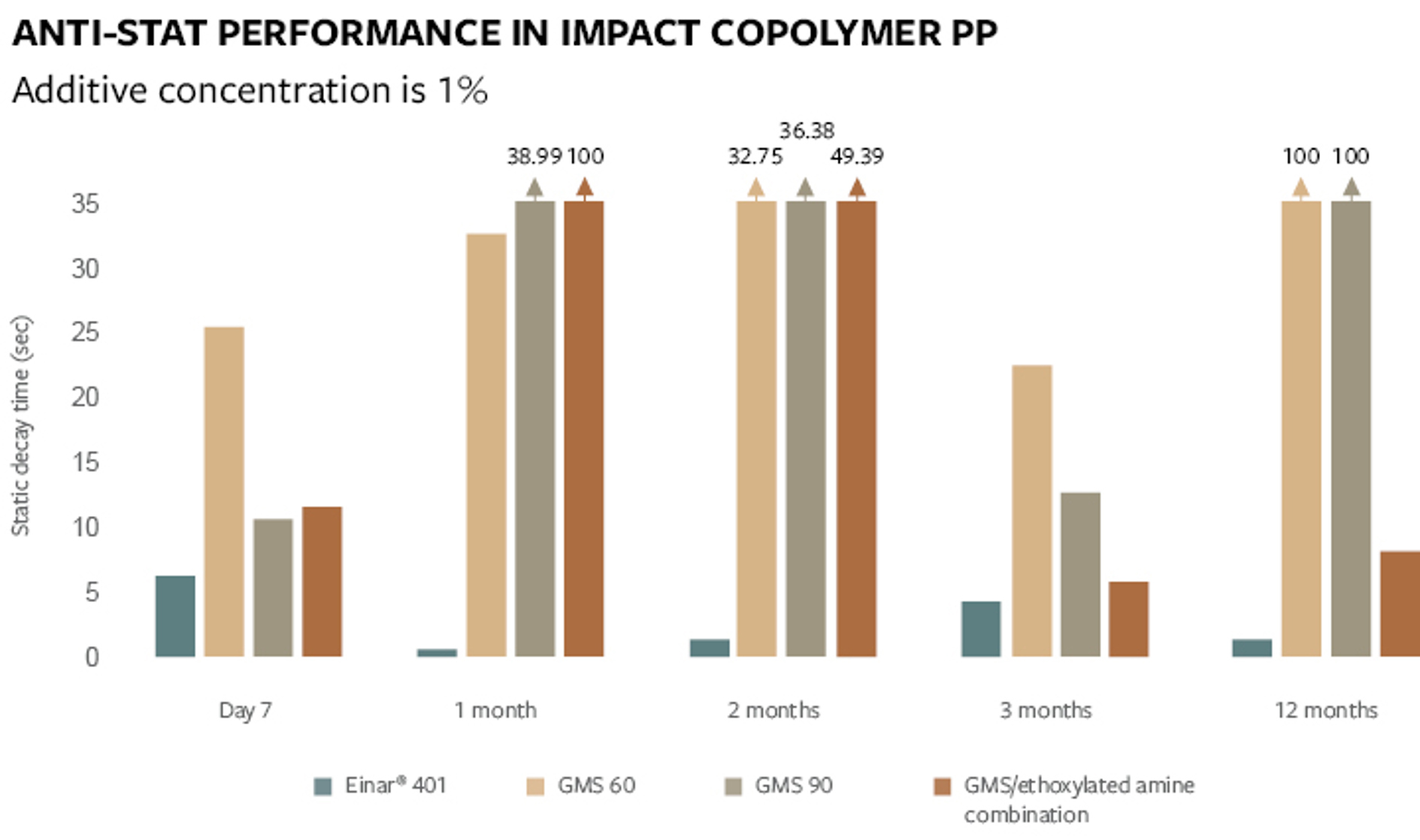

For moulders, it is not easy to achieve good anti-static performance with conventional anti-static agents in impact PP copolymers. As packaging designs are getting thinner, the challenge becomes even bigger, since the overall amount of the anti-static agent added is generally reduced relative to the surface wall-thickness of the packaging.

Palsgaard has developed Einar® 401, an anti-static product that works exceptionally well in this particular polymer and application range. Apart from preventing the build-up of static charges on the surfaces of injection moulded PP packaging, it also works as an internal lubricant and thereby helps manufacturers optimise their moulding process and reduce cycle times. Likewise, it can effectively eliminate friction problems that are often created by high static energy during mould release, on conveyor belts and during stacking.

The most efficient way of protecting packaging application surfaces from attracting dust is to incorporate the anti-static agent as a migratory additive into the polymer matrix during compounding. To this end, Einar® 401 performs equally well as a neat additive or as part of an additive masterbatch.

With many polymer additives, migration is an undesired property and of particular concern with regard to human health when the packaged product is food. For anti-static agents, however, migration to the surface of the package is a must, since only there will the additive be able to react with ambient moisture and form a conductive layer that will effectively dissipate static charges.

The migratory performance is closely dependent on the polarity and crystallinity of the polymer as well as on the wall-thickness of the packaging and the additive concentration required to ensure the anti-static function. Still, any additive that migrates in the packaging inevitably becomes an indirect additive of the packaged product. This has increasingly caused concern among consumers and has resulted in strict regulations intended to limit the amount of certain migratory additives in food packaging.

The concerns over migratory additives in food-contact containers and other food packaging are not new. A particular category of chemicals that has moved into the focus of responsible manufacturers more recently is the ethoxylated amines in conventional synthetic additives, including anti-static agents for use in food-contact polypropylenes.

In this context, it is important to recognise that most Einar® products are not subject to any specific migration limits. This is due to the fact that they are derived exclusively from edible and renewable plant sources.

In chemical terms, most Einar® products are glycerol esters made exclusively from vegetable oils distinguished by their fatty ester profiles and degree of saturation. Sources include certified palm oil, which provides the greatest yield per hectare, followed by rapeseed, sunflower, and other vegetable oils from plants that are not in competition with the human food chain. As a result, all Einar® polymer additives are FDA and EU as well as kosher and halal approved for food-contact applications.

In order to ensure the long-term anti-stat performance of Einar® anti-static agents, the migratory profile is modified to meet with the polarity of the polymer and maintain its desired function also in thinner packaging and even at reduced concentration levels. For example, Einar® 401 shows superior anti-static performance over time vs. conventional blends of glycerol mono-stearates and ethoxylated amines at reduced concentrations.

This applies in particular to the elimination of anti-stat issues often encountered in winters and in low-humidity cold climate regions. And as the plastics industry is becoming increasingly circular, this also means that the bio-based additive has little – if any – impact on the recycling of post-consumer packaging, whether chemically or mechanically. Besides, Einar® additives are generally not known to degrade into harmful compounds which might contaminate the recycled material, or promote discolouration or loss of properties.

Palsgaard’s polymer additives are named Einar® in memory of the company’s founder, Einar Viggo Schou, who invented modern plant-based emulsifiers back in 1917 to reduce spattering, prevent thermal shock, control viscosity and facilitate aeration in food processing. Backed by their fundamental ability to mix oil and water, the emulsifiers were eventually found to offer significant benefits also as functional polymer additives in non-food applications, such as packaging materials. There, Einar® anti-stat and anti-fog agents have emerged as reliably safe and efficient surfactant additives in the food packaging industry.

Palsgaard produces its plant-based additives with a strong focus on reducing energy consumption and CO₂e emissions across operations, in line with our ESG commitments. These additives are designed to support innovative packaging solutions that aim for resource efficiency and recyclability, while offering a practical alternative to fossil-based additives in many polymer formulations.

As a dedicated anti-static solution for polypropylene – including impact PP copolymers used in thin-wall packaging – Einar® 401 demonstrates how bio-based technology can combine performance with responsibility. It provides brand owners, designers, and converters with an option that meets food-contact standards and supports sustainability objectives without compromising quality or processing efficiency.

Palsgaard offers technical support and expertise to assist manufacturers in the proper utilisation of Einar® additives. This guidance ensures that manufacturers can effectively incorporate the additives into their production processes while maximising safety and performance.

About the author: Bjarne Nielsen was Global Industry Manager at Palsgaard A/S and was responsible for Einar® food-grade additive development for polymer applications, including food and non-food packaging. With more than 25 years of experience in the development and sales of additives derived from plant-based raw materials, Nielsen had a solid background in natural chemistry and holds several product patents. He retired in 2024.

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE