TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

Perfecting ice cream's melting resistance marries science and consumer desires. Palsgaard's Claus Prior Hansen highlights how this visual quality shapes enjoyment. Tailoring to individual preferences – slow melt for some, quick for others – Palsgaard's emulsifier/stabiliser solutions, like Palsgaard® ExtruIce and Palsgaard® MouldIce, fine-tune the experience.

"When we talk to customers, we talk about their whole processing, and we’re often looking to see if there are other factors we can adjust. Emulsifiers are critical but you need that total overview."

— Claus Prior Hansen, Application Manager, Dairy And Ice Cream, Palsgaard A/S

“Melting resistance is usually one of the first things our customers want to talk about,” says Claus Prior Hansen, Application Manager, Ice cream & Dairy, at Palsgaard. “It’s extremely important because it’s so visual and so obvious to consumers. When little Peter is eating his ice cream, if he’s taking his time, suddenly he’ll find that half of it is on the floor.”

So what’s the ideal melting resistance? “There are as many views on that as there are producers and consumers,” Claus says. “I can visit one customer who wants a product that will stand on the table for an hour and a half and keep its shape. And right next door to them, there’s another who wants something that starts to melt in ten or fifteen minutes, because if it doesn’t, it won’t look like ice cream. It’s all in the eye of the beholder. We don’t set the goal – the customer does, and it’s up to us to find a way to achieve it.”

He adds that the application is also a major consideration. “If it’s a single-serving product, like a cone or a sandwich, it needs to have relatively strong melting resistance, because it’s going to be held in someone’s hand. Whereas products that are sold in larger volumes – family-size buckets for example – don’t necessarily need such strong resistance.”

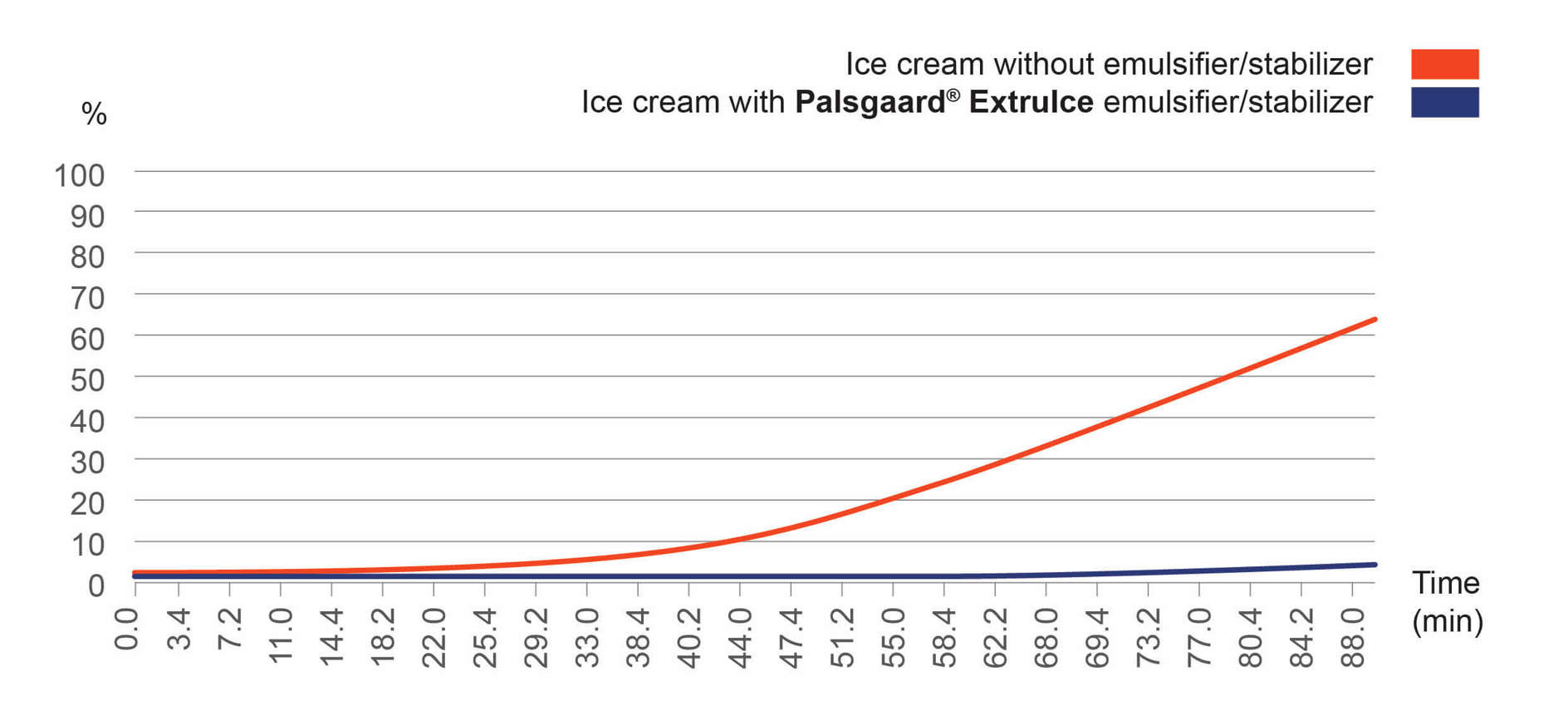

The good news is that the right ingredients can help regulate the melting properties of ice cream. Emulsifiers place themselves in the layer between fat and water, displacing the protein on the fat globules and reducing surface tension. As well as benefits like improving mouthfeel, this affects the stability of the ice cream and the speed at which it melts.

Palsgaard’s emulsifier solutions include the Palsgaard® ExtruIce range for extruded ice creams – typically single-serving products like cones that need a stronger emulsifier. Meanwhile, the Palsgaard® MouldIce range is perfect for moulded ice creams, which tend to require a less powerful melting resistance.

Claus works with customers to achieve exactly the right emulsifier-stabiliser combination for their needs. “Melting resistance is definitely something we can influence, correct and improve upon,” he says. “Switching emulsifiers is the easiest way to get a benefit – we can do a lot just by changing from one Palsgaard® ExtruIce product to another.”

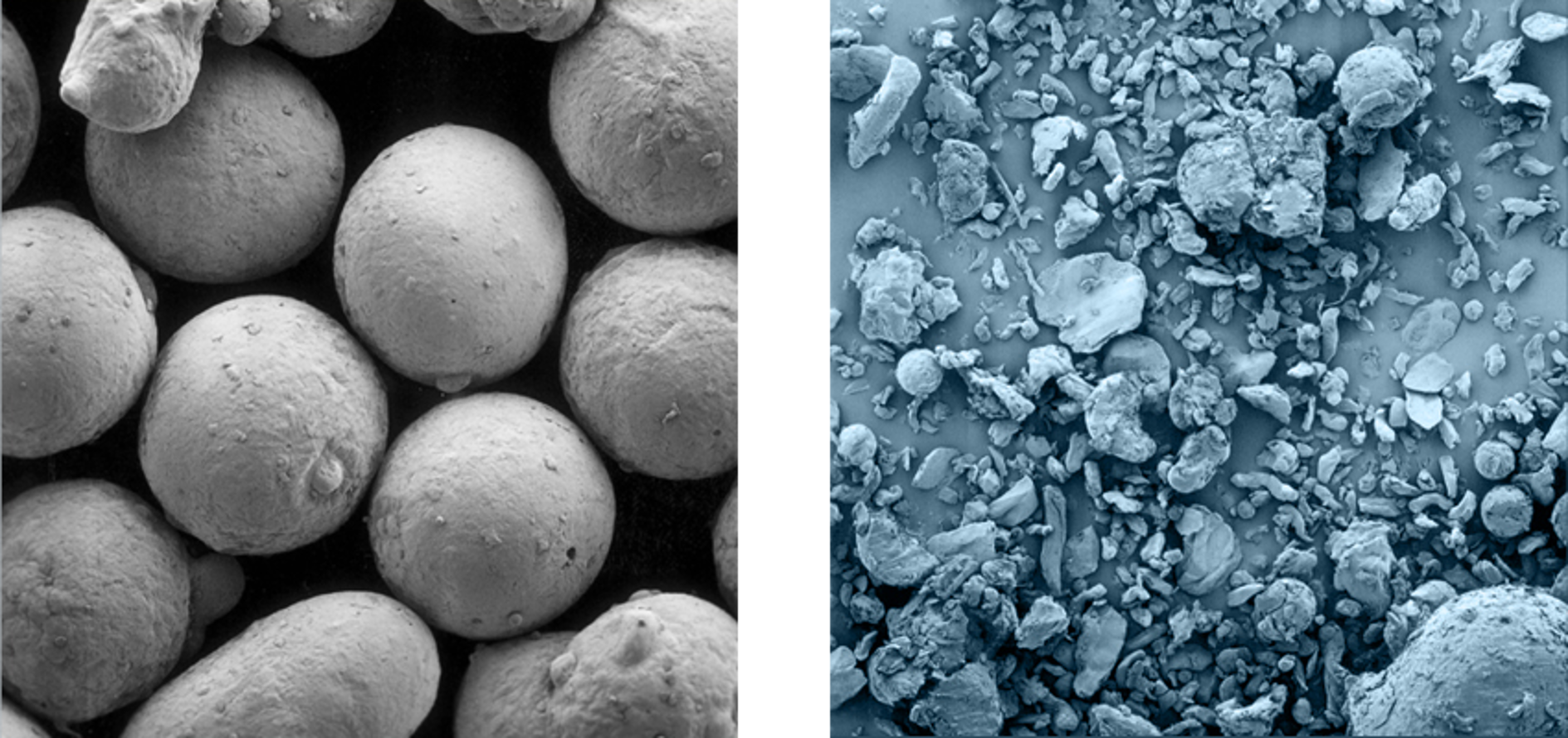

Unlike many alternatives on the market, Palsgaard’s products are fully integrated blends. “The stabiliser is covered by emulsifiers in a powder,” Claus explains. “That makes it very easy to handle and very easy to add to the liquid because it’s highly dispersible. The alternative is having to mix two or three powders, which is more time-consuming.”

However, strategies to control melting resistance need to be based on more than science – consumers’ health needs, and their ethical concerns, increasingly have to be factored in. “A lot of ice creams used to contain PHOs (partially hydrogenated oils),” Claus says. “In the past, that wasn’t seen as a bad thing, because it was a good way of improving melting resistance. However, they’re a source of trans fats, so right now there’s a lot of pressure to go PHO-free.”

The other big demand is for products that are palm oil-free. “We’ve been working a lot on those areas,” Claus says. “It’s been a bit of a challenge to get the same functionality and mouthfeel as well as melt resistance, but now we can provide products that meet all those needs. For example, we’ve just launched a new range of emulsifier-stabiliser blends which contains guar gum that are both palm-free and PHO-free. That’s the way the market is moving, and by being able to offer them, we’re a little bit ahead of some of our competitors.”

Growing concern about climate change has also meant that Palsgaard is being called on to improve the melting properties of plant-based frozen desserts. “The process is parallel to traditional dairy ice cream in some ways,” Claus says. “We can control a lot of the factors but it’s a little more complex because there are so many different raw materials – soy, almond, coconut, for example. The good thing is that our emulsifiers are based on vegetable oil and our stabilisers are plant-based, so they’re ideal for non-dairy products.”

You can find out more about Palsgaard’s solutions for plant-based desserts here.

CLAUS PRIOR HANSEN'S TOP THREE TIPS FOR CONTROLLING MELTING RESISTANCE:

TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE