TECHNICAL ARTICLE

TECHNICAL ARTICLE

Discover how Palsgaard's innovative stabiliser blends are transforming egg-free or egg-reduced mayonnaises, providing manufacturers with consistent texture, viscosity, and flavour while navigating the challenges of fluctuating egg costs. Embrace a new era of culinary creativity and cost-efficiency in dressing manufacturing with Palsgaard® 5423 and Palsgaard® 5426.

As most people know, traditional mayonnaise consists of two primary ingredients: oil and egg yolks. In fact, the word “mayonnaise” may even have been derived from moyeu, the medieval French word for the yolk, meaning centre or hub – but that’s still being debated. Whatever the truth may be, there’s no denying the fact that both ingredients are subject to dramatic price fluctuations that make life difficult for mayonnaise and dressing manufacturers.

In 2004, for example, an outbreak of avian flu in Asia hit the world’s poultry industry – and liquid egg prices rose 20 to 30 percent over 12 months. And in 2013, the US experienced an unprecedented oversupply of egg yolks as major fast-food chains increased offerings of healthier, egg white-based alternatives for breakfast.

These two examples only scratch the surface of an issue that has become increasingly important to manufacturers: how to reduce the content of egg yolk in dressings without sacrificing critical production parameters or sensory properties such as texture, viscosity, flavour-release or flow.

Of course, there are limits to how much egg content can be reduced before a product can no longer be described as mayonnaise. In the US, for example, the FDA defines mayonnaise as an emulsified, semi-solid food prepared from vegetable oil, lemon and/or lime juice, and an ingredient containing egg yolk. Similar stipulations exist in Europe and other parts of the world. Removing the yolk entirely, therefore, without re-designating the product is likely to cause adverse reactions from both regulatory authorities and consumers.

That said, today the sky really is the limit. Using carefully combined stabiliser blends with emulsifying effects, manufacturers can freely determine the nature and content of their products, creating both egg-free and egg-reduced recipes with sensory and rheological properties similar to traditional mayonnaises and dressings.

Egg yolk has long been used as a natural emulsifier between the oil and water phases in mayonnaise and dressing. This emulsifying capability is mainly related to its content of lecithin, typically lying around 1.2 percent. Pasteurised whole eggs or whole egg powder may also be used as emulsifiers as long as there is sufficient egg yolk content to create and maintain a stable emulsion.

Adding stabilisers to a mayonnaise recipe affects the rheological properties of the water phase in oil-in-water emulsions. Egg yolk-reducing or replacing emulsifier and stabiliser blends like those developed by Palsgaard incorporate modified starches such as acetylated distarch adipate (E1422), hydroxy propyl distarch phosphate (E1442) and sodium octenyl succinate (E1450). They may also include, for example, stabilisers such as guar gum (E412) and xanthan gum (E415).

While modified starches have become a strong solution to the egg yolk reduction challenge, their structure and properties, particularly the degree and type of modification, can present significant obstacles to creating an optimally functional stabiliser blend.

Palsgaard’s development team have resolved such difficulties by applying the emulsifying properties of sodium octenyl succinate (E1450), the ability of hydroxy propyl distarch phosphate (E1442) to create creaminess, and the extra viscosity provided by acetylated distarch adipate (E1422). Together, these components deliver the right balance between viscosity, creaminess, mouthfeel and stability both during processing and shelf-life.

When applied to the production of vegetable-based mayonnaises that don’t contain egg yolks, milk or vegetable proteins, or emulsifying starches, the Palsgaard stabiliser blends can act as an emulsifier – as long as their properties match the requirements of an oil-in-water emulsion.

Of course, there’s more to it than simply adding a standard blend of stabilisers and expecting that all will be well. Getting the exact composition of a stabiliser blend right for your specific mayonnaise takes experience, as well as in-depth knowledge of the functional properties of the individual stabiliser.

A key factor to consider is the mayonnaise’s desired fat content. In fact, using a stabiliser blend suitable for a particular level of fat allows product developers to begin by creating an egg-free version of an existing recipe with similar viscosity and mouthfeel. Once that’s achieved, they can then decide for themselves (perhaps together with Marketing) how much egg yolk is appropriate to add and declare on the label.

Palsgaard has worked with stabilisers for decades and is an expert at developing just the right formulations of stabilisers for different purposes. The company offers two emulsifier and stabiliser blends (Palsgaard® 5423 and Palsgaard® 5426), which can be used in egg yolk-free (vegetable) and egg yolk-reduced mayonnaises. Palsgaard® 5423 is typically used for mayonnaise or dressing with fat content of 0 to 40 percent, while Palsgaard® 5426 is better suited to products with 40 to 60 percent fat. Both blends create homogeneous and stable emulsions with excellent mouthfeel and are labelled as allergen-free.

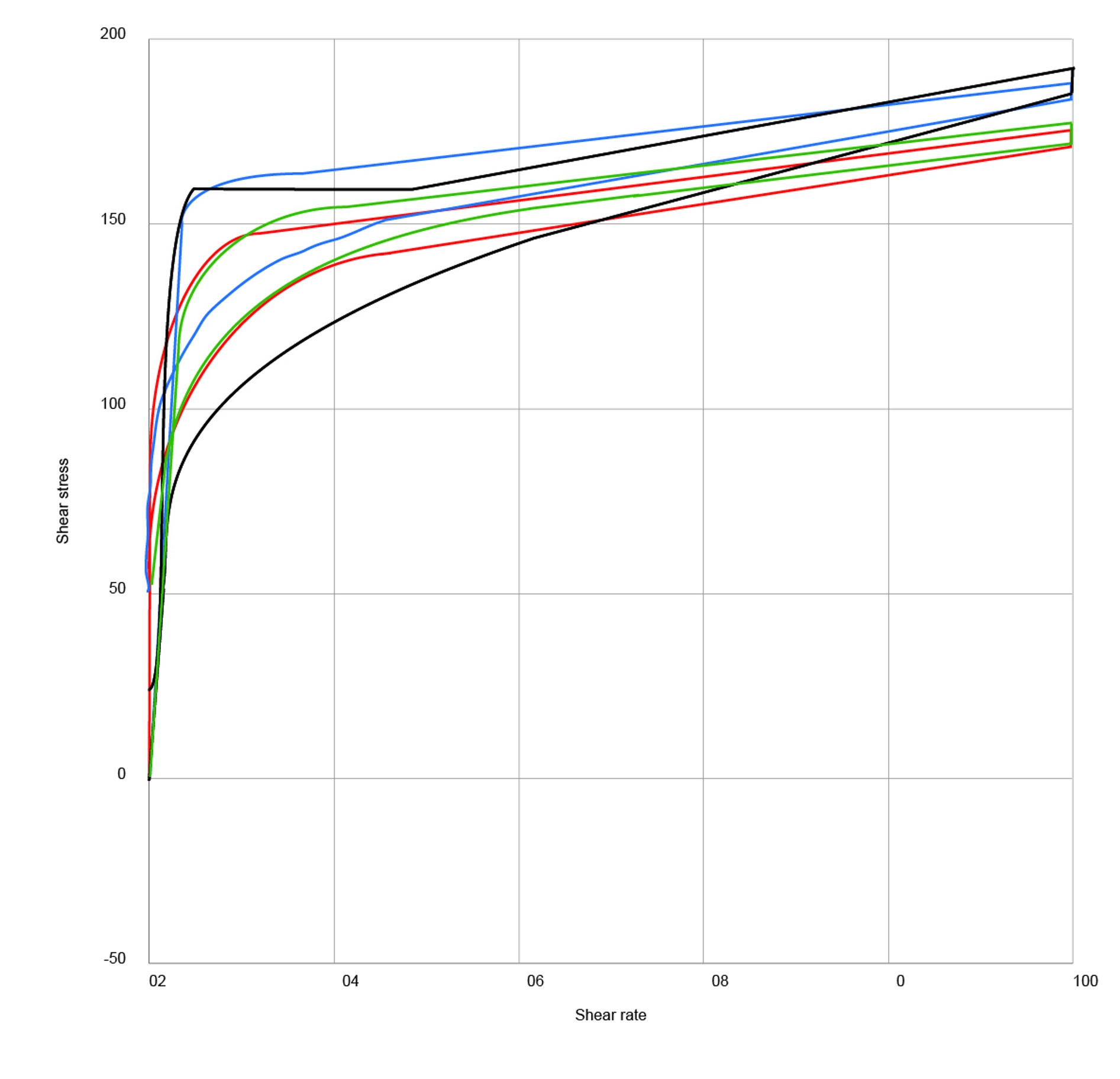

These two stabiliser blends are proven to meet the challenges of both rheological (including texture, viscosity, flow) and sensory (such as creaminess, mouthfeel, flavour release) properties when used in mayonnaises and dressings with a fat content ranging from 0 to 60 percent fat.

To create an egg-reduced or egg-free recipe, you need to determine the amount of eggs, the desired viscosity and the mouthfeel of the existing product, allowing for the fact that the consistency of mayonnaise and dressings can vary greatly from region to region – and from recipe to recipe. The new recipe is then developed on the basis of these measures, and extensive pilot plant trials are used to test its accuracy. For Palsgaard’s customers around the world, this work is most often conducted at one of the company’s regional application centres. Analytical methods and viscosity testing are typically carried out using a Haake viscosimeter or a Brookfield instrument. Once the basic recipe has been defined, achieving the desired egg content, viscosity and mouthfeel, the customer is finally ready to fine-tune taste aspects.

Today’s emulsifier and stabiliser blends enable mayonnaise manufacturers to create both egg-reduced and egg-free recipes with the mouthfeel and viscosity their customer's demand – yet with greater control over raw material costs. It’s a winning proposition that is sure to appeal to production cost managers and price-sensitive retailers alike.