Palsgaard expands CO2-reporting

At Palsgaard, we are committed to reducing the CO2-footprint of our business, which is why we are now upgrading our reporting on emissions.

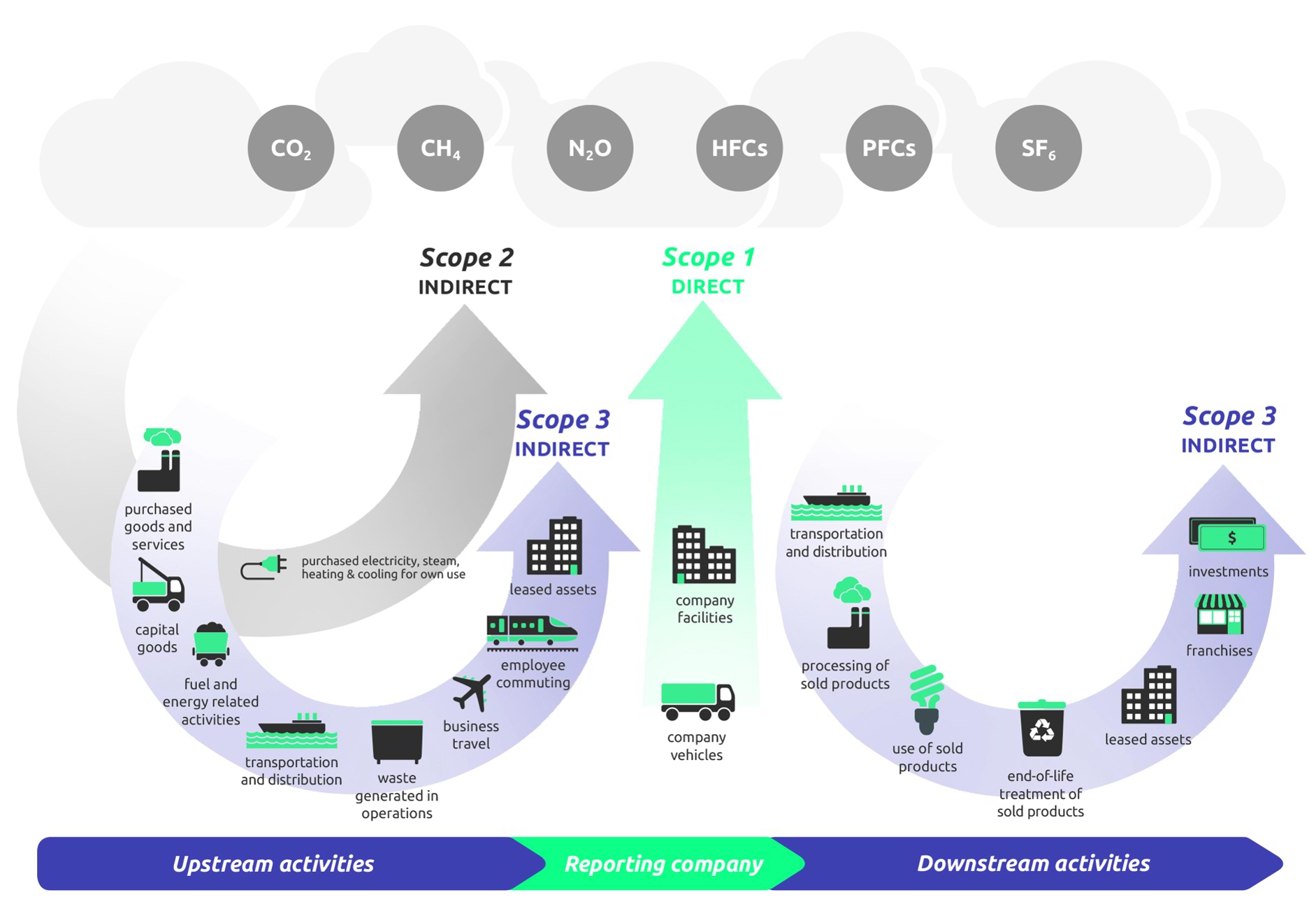

Starting in 2024, reporting on CO2 emissions will include our whole value chain, i.e. scope 1, 2 and 3 emissions. Scope 3 emissions are currently only available for Palsgaard’s operations in Denmark, but in 2024, we will be taking steps to map and quantify Scope 3 emissions across all our production sites.

We have made this decision to give a more accurate and comprehensive overview of Palsgaard’s environmental impact, and to prepare for CSRD-reporting in 2025.

Not only will this improve transparency for our stakeholders, but it will also make it easier for us to prioritise and develop our reduction efforts.

As a consequence of this new reporting practice, we will no longer claim that our products are "Produced in CO2-neutral factories".

This claim was based on a combination of efficient energy optimisations and green energy sources, supported by offsets governed by the United Nations Framework Convention on Climate Change and was verified by Deloitte in our annual CSR reports.

“Produced in CO2-neutral factories” included scope 1 and 2, and so did not include emissions from our value chain. This approach does not reflect Palsgaard’s new level of ambition on the climate agenda.

We will continue to analyse our activities and value chain and work closely with suppliers, customers, and other stakeholders to identify specific reduction potential in our CO2-emissions.

We will continue to invest in and support projects that reduce carbon emissions, promote renewable energy and contribute to a more sustainable future.